Fabricator and hot rod enthusiast Dennis Wheeler cruises down a Colorado mountain road in his custom built roadster. Doing all his own work, Wheeler rebuilt his modified 1948 F-1 Ford from the ground up. Because Wheeler wanted a completely custom and unique hot rod, aquiring parts was not as easy as ordering from a catalog. Wheeler needed to custom manufacture parts to get a perfect fit. As a fabricator by trade he started out producing the needed parts by hand. Although he was successful, the time and effort it took was too much. Also, he was never able to get the exact cuts or sizes that he need. He found a solution in one key tool, the PlasmaCAM.

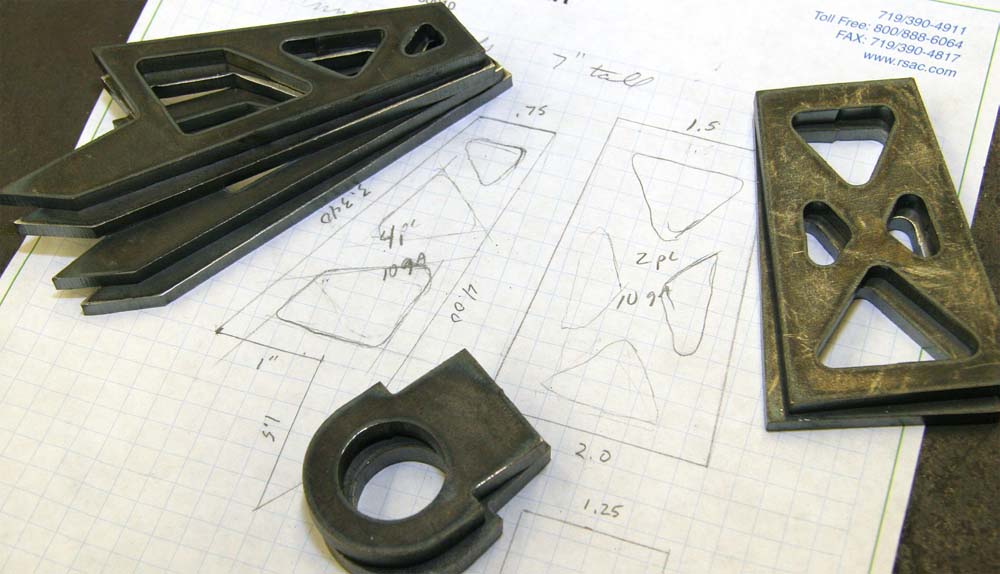

The PlasmaCAM is a robotic tool used to cut any intricate shape out of metal. He used the PlasmaCAM to cut a variety of metals such as mild steal, stainless, and aluminium. He produced many parts including the trim, motor mounts, frame pieces, sections of the body, and parts of the interior. Wheeler stated, “In the past, hand cutting my metal parts took time and they weren’t exact enough. The front grill of my Ford had to have each piece be exactly the same to fit together. I could only get this level of precision by using the PlasmaCAM machine.” With the PlasmaCAM, Wheeler not only was able to produce the parts he needed with more ease and precision, the machine also cut his production time in half. For further information on how you can make customizing your ride even simplier contact PlasmaCAM today.